12V, 24V or 48V? Not sure which voltage you should choose? Here’s a comprehensive guide to help you select the correct voltage for your modern electrical system. By modern, I mean using lithium batteries. Lithium batteries have significantly lower internal resistance and therefore much less voltage sag under load compared with lead-acid batteries. Because of this, a 12V lithium system can do much more than a 12V lead-acid system.

For the rest of this article, I’ll only be talking about lithium batteries.

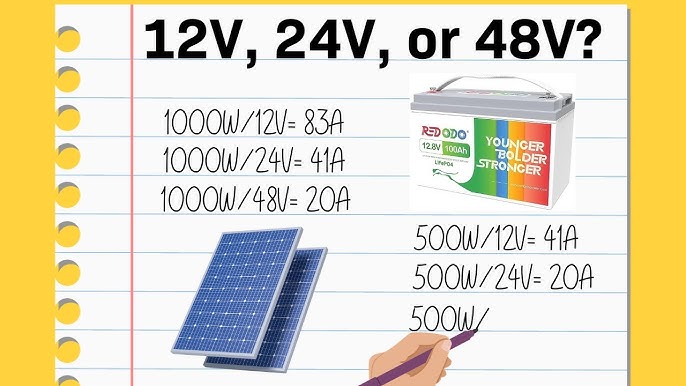

Let’s say you want to run a 3kW inverter. Amps = power ÷ voltage, so:

Most people don’t know that the heat generated from wire resistance is proportional to the square of the current. To combat this, moving from 48V to 24V requires four times the copper cross-section, and moving from 48V to 12V requires 16 times larger wire. Because of this, there’s a practical limit to where it doesn’t make sense to run a 12V system anymore—around the 300A mark. It is possible to go higher, and I’m running 600A through my 12V system, but you need a specific use case. Mine is direct alternator charging.

Because a 48V 3kW inverter requires 16 times smaller copper traces than a 3kW 12V inverter, 48V systems will generally be cheaper for the same quality. Although higher voltage components are more expensive, it is still significantly cheaper to produce a 48v inverter. The same applies to solar controllers.

The downside of higher voltages is that there’s much less support for products. 48V lighting, water pumps, and USB chargers are almost non-existent or expensive due to low competition. If you run a 48V system, you’ll likely need a 48V-to-12V converter for low-current 12V devices. Alternatively, you could run everything through your 240V inverter, but you’ll need an electrician to wire it all up.

24V systems have better compatibility with low-current devices. There are many dual-voltage fridges, lights, and USB sockets, but you may struggle to find other products, like quality audio amplifiers, at a reasonable price. You do get the benefit of cheaper inverters and solar controllers, but if you’re already reaching the limits of a 12V system, the benefit of moving to 24V isn’t huge.

12V systems have by far the most support. Thanks to the low internal resistance of lithium batteries, running a 3kW inverter on 12V is easy and cheap, especially if you keep the cable lengths of high-amp devices to a minimum.

12V:

24V:

48V:

Please provide your details below and we will get in touch